Traditional timber box sash windows are marvels of Georgian and Victorian engineering that have graced British homes for over 400 years. These elegant, functional windows consist of numerous precisely crafted components working in harmony to create smooth operation and lasting durability. Understanding the anatomy of a sash window is essential whether you’re restoring period windows, specifying replacements with us, or simply curious about these architectural gems.

The Window Frame Structure

The Box Frame

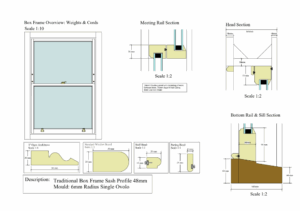

The foundation of any sash window is the box frame – a hollow timber construction built into the wall opening. This ingenious design houses the counterweight system that makes the windows operate effortlessly. The box frame consists of several key elements:

- Head: The horizontal top section of the frame that bears the structural load and houses the pulley wheels.

- Jambs: The vertical side sections containing the deep cavities where the sash weights travel up and down.

- Sill: The sloped bottom section designed to shed rainwater away from the building.

- Parting Bead: The central vertical strip that separates the upper and lower sash windows, allowing them to slide past each other.

- Staff Bead: The inner vertical strips that hold the lower sash in place and provide a smooth-running surface.

This box construction gives the “box sash” window its name and forms the crucial framework that enables the entire counterweight system to function effectively.

The Sash Components

The moveable elements of a sash window are precision-engineered timber frames that slide vertically within the box frame. These sashes must be perfectly balanced and precisely fitted to ensure smooth operation and weather-tight sealing.

Upper and Lower Sashes

Each sash window features two moveable frames called sashes:

- Meeting Rails: The horizontal timber sections where the upper and lower sashes overlap when closed. The lower sash has the upper meeting rail, while the upper sash has the lower meeting rail.

- Stiles: The vertical timber pieces forming the sides of each sash frame.

- Glazing Bars (Astragals): The slender wooden dividers that create the characteristic grid pattern and can also hold individual panes of glass.

- Bottom Rail: The lower horizontal member of the bottom sash, typically thicker to provide structural strength.

- Top Rail: The upper horizontal member of the top sash.

These carefully jointed timber components create robust, long-lasting sashes that maintain their shape and operation for decades when properly constructed and maintained.

The Operating System

Modern sash windows use one of two proven systems to counterbalance the weight of the sashes, ensuring smooth operation:

Traditional Counterweight System

The classic approach found in period properties and authentic reproductions:

- Sash Weights: Cast iron weights, typically weighing half the total weight of each sash, enabling effortless operation.

- Sash Chain or Cord: Strong chains or ropes connecting the sashes to their counterweights. Traditional hemp cord was common, though chain is more durable.

- Pulleys: Brass or iron wheels housed in the head of the frame that guide the chains/cords smoothly.

- Pockets: Removable sections in the frame allowing access to the weight compartments for maintenance.

Modern Spring Balance System

Modern Spring Balance System

A contemporary solution that offers a similar smooth operation in a more compact design:

- Spring Balances: Pre-tensioned spiral springs that counterbalance the sash weight without requiring deep box frames or wall cavities.

- Compact Housing: The spring mechanism fits within standard frame depths, making it ideal for new builds or properties without traditional box frame construction.

Both systems transform what would otherwise be heavy, difficult-to-operate windows into effortlessly smooth mechanisms that provide years of reliable service.

Hardware and Fittings

The functional and aesthetic details of a sash window rely on carefully selected hardware and fittings. These components not only ensure secure operation and weather protection but also contribute significantly to the window’s traditional character and visual appeal.

Security and Operation

- Sash Fasteners: The traditional brass or iron catch where the meeting rails join, providing security and weather-sealing.

- Sash Lifts: Small handles or grips fitted to the bottom rail of the lower sash for easy operation.

- Window Furniture: Period-appropriate handles, stays, and decorative elements that complement the window’s character.

Draught-Proofing Elements

- Draught Seals: Modern additions to traditional windows, these are fitted discretely to improve thermal efficiency while maintaining authentic appearance.

- Weather Strips: Brush or compression seals fitted between moving parts to reduce air infiltration.

Glazing and Weathering

The performance and longevity of a sash window depend heavily on proper glazing installation and effective weather protection. These elements work together to create a barrier against the elements while maintaining the window’s aesthetic appeal and thermal efficiency.

Glass and Glazing

- Double Glazing Units: Our new replacement timber sash windows typically feature sealed double glazed units that dramatically improve thermal efficiency and noise reduction while maintaining the traditional aesthetic.

- Heritage Single Glazing: Crown glass or cylinder glass with traditional hand-made character is generally reserved for listed buildings and heritage projects where conservation requirements mandate authentic materials.

- Glazing Beads: Timber mouldings and Chamfered Beading hold modern glazing units securely in place, often removable for glazing replacement.

- Glazing Putty: While traditional linseed oil-based putty can be used for heritage work, modern glazing methods using timber beading offer improved durability and weather resistance for replacement windows.

The glazing system forms the primary barrier against weather infiltration and provides the thermal performance that makes sash windows comfortable year-round.

External Protection

- Weatherboard: A projecting timber section above the frame that deflects rainwater.

- Drip Groove: A channel cut into the underside of the sill to prevent water running back toward the wall.

- Paint System: Multiple coats of Micro Vapour Permeable, Microporous paint providing weather protection and authentic appearance.

These external protection measures work together to shield the timber structure from moisture damage while directing water away from vulnerable joints and connections, ensuring decades of trouble-free service.

Maintenance Considerations

Understanding these components helps identify common issues:

- Sash chord failure rarely occurs but requires access through the pockets to replace worn cords or chains if necessary.

- Glazing putty deterioration needs careful removal and replacement to maintain weatherproofing.

- Paint system maintenance protects the timber and maintains the window’s appearance.

- Hardware lubrication ensures smooth operation of pulleys and fasteners.

Restoration or Replacement Sash Windows?

When properly maintained, our traditional wooden box sash windows can last centuries. Each component can be repaired or replaced individually. Understanding the anatomy helps determine whether your existing windows need minor repairs, component replacement, or you need to speak with us about our specialism – Upgrading to double glazing via new sashes or complete sash window replacement including the box frames.

Conclusion

The traditional timber box sash window represents centuries of refined craftsmanship and engineering. Every component serves a specific purpose in creating windows that are both beautiful and functional. Whether you’re a homeowner with period property, a restoration professional, or an architect specifying new traditional-style windows, understanding this anatomy ensures these magnificent windows continue to grace our buildings for generations to come.

For expert advice on sash window restoration or traditional replacements, contact the specialists who understand every component of these remarkable windows.

Call our friendly, knowledgeable team on 0800 389 7384.